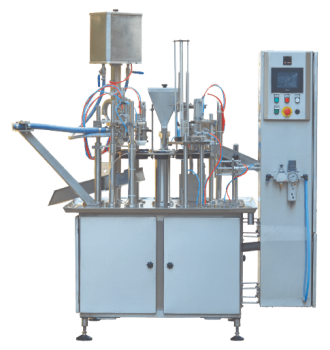

Micron Ice Cream Cup and Cone Filling machine is available in Rotary as well as Linear with a capacity ranging form 3000 — 12000 Cups and Cone Per Hr. The machine is made in complete AISI 304 and product contact parts in AISI 316. The machine is a combination of Mechanical and Pneumatic mechanism. This help to reduce air requirement and hence the power consumption. Servo Machines are made available on request.

| Specifications | Description |

|---|---|

| Models | Different Models Available as per required Capacity |

| Capacity | 3000 – 12000 for Cups in Rotary Machine 3000 -6000 Cone In Rotary Machine 8000 -12000 Cone In Linear Machine |

| Number of Lanes | Single to Six Lane as per Model . Higher Lane models are also available as per requirement . |

| Type of Cups | Machine suitable for plastic /Paper Cups with Paper lids Machine are suitable for IML Cups with Plastic Lids. Machines also available for TUBS for 750 ml upto 4 Ltrs |

| Special additions | Machines can be supplied with Rotary Nozzle. Filling Nozzles are supported for Ripple pump for special cup filling Filling nozzle also support Fruit Feeder for Nut filling with Ice Cream. Pick & Place for Linear Machine is Possible |

| Interlocks | NO – CUP – NO OPERATIONS EXCEPT FILLING |

| Operation | All Machines are PLC (Programmable Logic Controller) operated |

| Components | Description |

|---|---|

| Indexing | Robust stainless steel frame providing stability and support for the machine |

| Frame | Mechanical Indexing which Guarantee accurate centring . Custom design for SERVO INDEXING possible. |

| Rotary table | Constructed from stainless steel for durability and corrosion resistance |

| Dosing System | Precision dosing system for consistent filling |

| PLC Control Panel | User-friendly interface with a PLC (Programmable Logic Controller) for setting and monitoring operations |

| Filling Nozzles | Plain and Flower type made of Food Grade Plastic |

| Chocolate Spray | Air Less Chocolate spray nozzle available with MICRON |

| Volume Adjustment | Synchronised with Freezer out put |

| Synchronisation | Higher Capacity Linear Machines can be synchronised with Hærdning Tunnel |

| Control Panel | The control panel houses both electrical and pneumatic components with IP 55 Protection. |

Micron has designed and developed High Pressure Homogenisers for products like Milk, ice Cream Mix, Dahi

Micron has designed and developed flexible rotary type cup filling and sealing machines.

Our innovative solutions maximize productivity and offer unbeatable value in the packaging industry.

Micron has designed and developed an Automatic Stick-Line Machine for ice cream.

The Micron Cube Forming machine is designed to pack butter and similar kind of products in parchment paper or aluminium

The Micron Cube Forming machine is designed to pack butter and similar kind of products in parchment paper or aluminium

Our innovative solutions maximize productivity and offer unbeatable value in the packaging industry.

Micron has been key player in our journey of ice cream manufacturing. We bought two cone making and packing machines. Service is absolute top notch and management is very helpful. In the laps of Uttarakhand where we are located they are providing such great service. I sincerely thanks micron for their support and they well engineered machines

Micron’s exceptional service and quality machinery have exceeded our expectations and contributed significantly to our success.

Thank you & we look forward to continue our partnership.